Inconsistency in crop yield, due to human errors in fertilization was a major concern for this farm owner. He assigned a worker to manage the fertiliser mixing twice a day. With the SOPs provided to the worker, farm owner still experienced inconsistency in yields and not able to achieve the target weight (per bunch of salad) that he wanted. The owner decided to deploy REDtone Smart Fertigation System in his greenhouse on March 2021 and he is amazed with the result

Increase Crop Quality, Reduce Manual Handling And Inconsistency

With Smart Fertigation System

Location

Kuala Lumpur

Type

Indoor

Crop

Various green vegetable using NFT (Nutrient Film Technique) hydroponic system

Background

Inconsistency in crop yield, due to human errors in fertilization was a major concern for this farm owner. He assigned a worker to manage the fertiliser mixing twice a day. With the SOPs provided to the worker, farm owner still experienced inconsistency in yields and not able to achieve the target weight (per bunch of salad) that he wanted. The owner decided to deploy REDtone Smart Fertigation System in his greenhouse on March 2021 and he is amazed with the result

Location

Kuala Lumpur

Type

Indoor

Crop

Various green vegetable using NFT (Nutrient Film Technique) hydroponic system

Background

Inconsistency in crop yield, due to human errors in fertilization was a major concern for this farm owner. He assigned a worker to manage the fertiliser mixing twice a day. With the SOPs provided to the worker, farm owner still experienced inconsistency in yields and not able to achieve the target weight (per bunch of salad) that he wanted. The owner decided to deploy REDtone Smart Fertigation System in his greenhouse on March 2021 and he is amazed with the result

Data Collected After 3 Weeks

Before

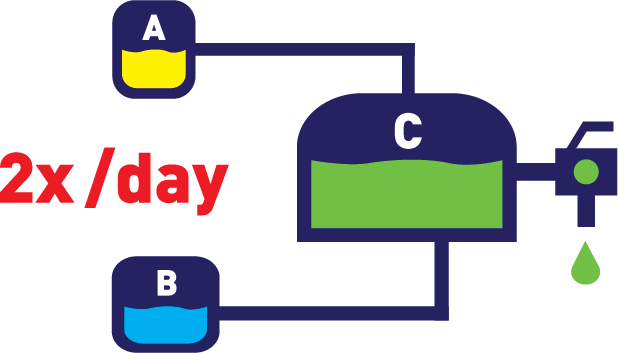

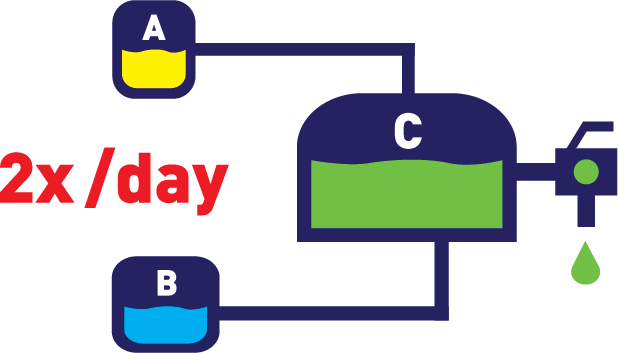

Manual Fertiliser Mixing Process

-

- Fully dependent on workers

- Errors and inconsistency were unavoidable

After

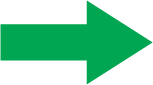

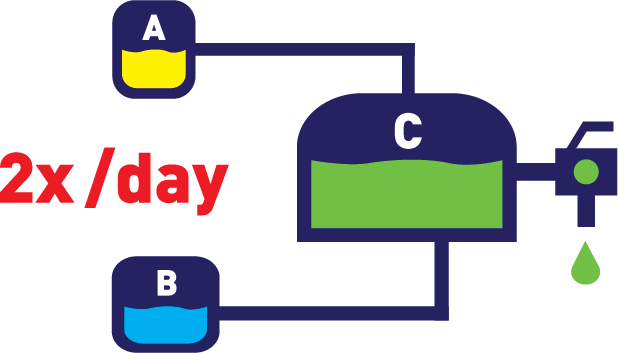

Automated Mixing System Following SOPs

-

- Accurate, uniform and precise as per EC target.

- Crops are well nourished

- Accurate, uniform and precise as per EC target.

Before

Inconsistency in Yield Weight

-

- Average 200gm to 210gm per bunch of salad

- Unable to increase the weight of crop even after few attempts of adjusting the SOPs

After

Yield Weight Increased By 50%

-

- Increased from 201g (previous cycle) vs 293gm per bunch of salad

Before

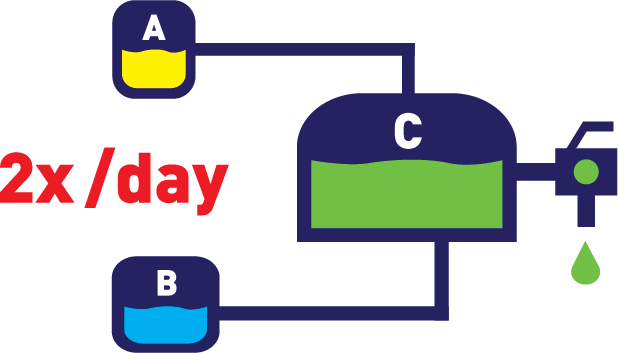

Manual EC Target Checking

- Assigned a worker to manually check the EC target 2 times a day

After

Automated EC Target Checking

-

- No manual checking required. All data are monitored via mobile phone and dashboard

Before

Manual Fertiliser Mixing Process

-

- Fully dependent on workers

- Errors and inconsistency were unavoidable

After

Automated Mixing System Following SOPs

-

- Accurate, uniform and precise as per EC target.

- Crops are well nourished

- Accurate, uniform and precise as per EC target.

Before

Inconsistency in Yield Weight

-

- Average 200gm to 210gm per bunch of salad

- Unable to increase the weight of crop even after few attempts of adjusting the SOPs

After

Yield Weight Increased By 50%

-

- Increased from 201g (previous cycle) vs 293gm per bunch of salad

Before

Manual EC Target Checking

- Assigned a worker to manually check the EC target 2 times a day

After

Automated EC Target Checking

-

- No manual checking required. All data are monitored via mobile phone and dashboard

Find Out More!

Get In Touch

Sales Enquiry

Sales Enquiry

Sales Hotline

1800 87 7770

+603 8084 8070

(if you are abroad)

Email Us

Customer Care

Customer Care

Support Toll Free

1800 87 7790

+603 8084 8910

(if you are abroad)